Now that the exterior part of the addition was complete, it was time to start work on the interior. The plans (that I designed and produced) had an “en-suite”, meaning an adjoining bathroom and other facilities. As a matter of fact, the design reflected my predilection for the “process” of getting ready for the day: do your business, brush your teeth and shave, shower, and then dress. Well, that’s my order. My wife’s order is not the same, so that meant that if we had a scheduling conflict, one could be in private for the “business end”, and the other could take care of the rest. But I digress….

At any rate, I had to construct the framework which meant erecting a wall, and then putting in false ceilings and compartments to define the elements of the space. I had to make the wall that separated the en-suite from the rest of the bedroom, and a couple of smaller walls that separated the toilet area from the shower and dressing areas. These two smaller walls also had to accommodate pocket doors. The framing for these walls was pretty standard (except for the pocket doors — more on that later), but I had to do some detail work to make sure that I had all the correct structural components figured out.

Interior wall construction is similar to exterior wall construction but if it’s a non-load bearing wall, you don’t have the same requirements, meaning that you don’t have to use structural grade lumber, and don’t have to have a bunch of connectors. However, because lumber and drywall are produced to standard dimensions, the rules on top plates, sole plates, and stud spacing generally apply. Other than applying exterior sheathing, the techniques for construction are exactly the same.

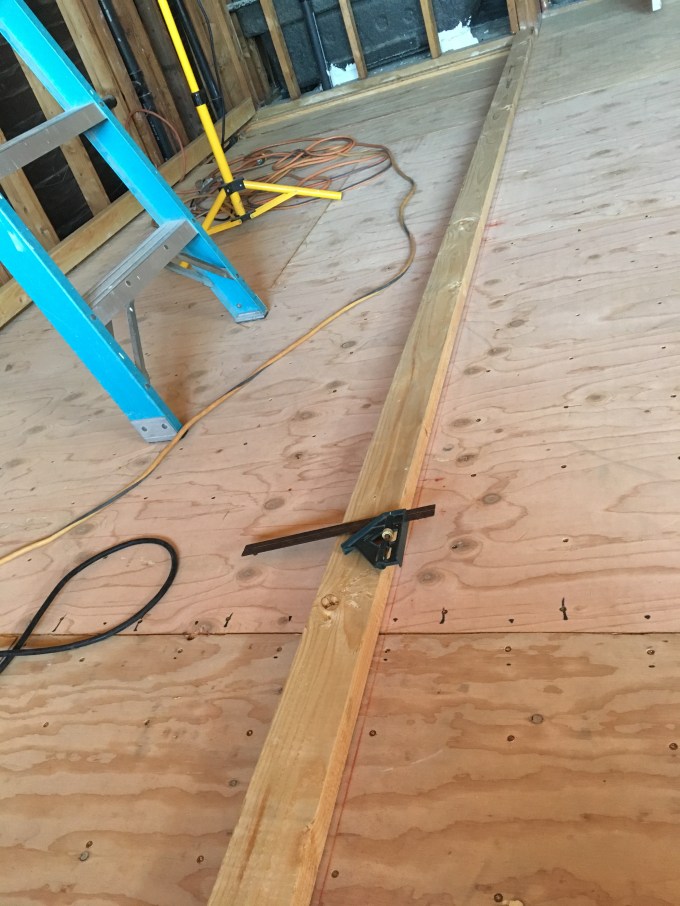

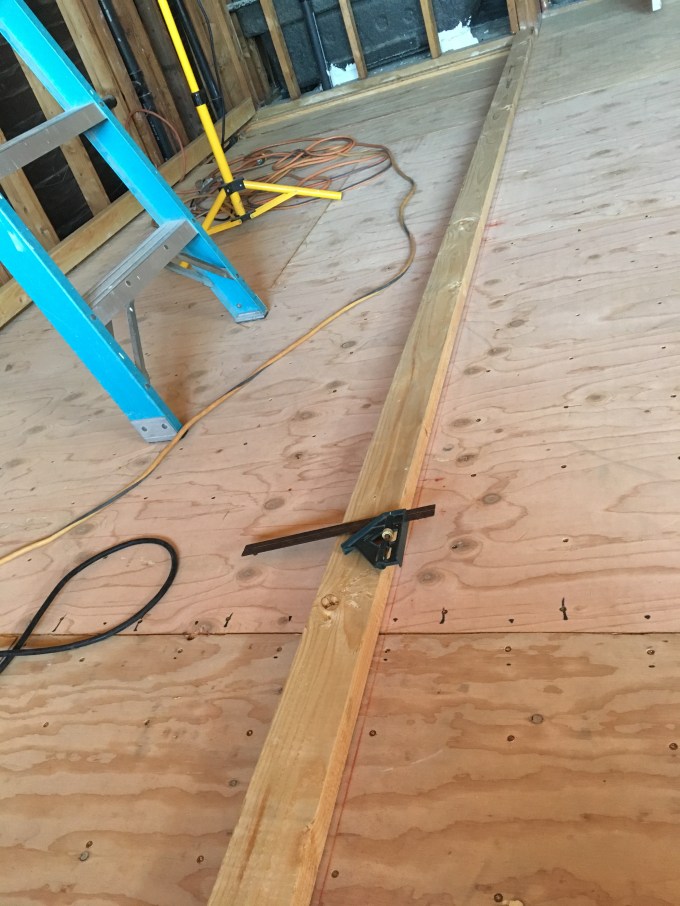

Step One: Measure and Mark. The best starting point for wall construction is to lay out the wall on the floor. Professional carpenters do this for all the walls at once because it both speeds the construction process, and but more importantly, it ensures accuracy and minimizes mistakes because you can see if everything fits together when you transfer all of the plan dimensions to full scale all at once. Not that there were any mistakes in the plans, mind you….(!)

(A) Locate the interior wall from a convenient reference. I used the existing exterior wall and the interior wall end that I had to marry up with.

Tools required for layout. If you’re doing this solo, then you need a handful of finishing nails and a hammer to hold the end of your chalk line (which I have in my belt, but neglected to photograph).

Plan for the wall. I drew this custom from my model. Typically you’ll just have a plan (overhead) view and have to figure out all of the vertical stuff, and I could have probably just done a quick hand drawing, but I’m also the designer, draftsman, and engineer, so I can do it how I want.

Location of sole plate from exterior wall framing.

(B) Check for square. Never assume that any previous work is perfect. Anything you build will have

errors that slowly build up and must be corrected for at each step.

Check marks to make sure they’re square before you snap the chalk lines. This is 63 3/4″ from the exterior wall.

Measure a convenient distance along the exterior wall.

Calculate the hypotenuse of the triangle using the good old Pythagorean Theorem which you learned in middle school (you did, right?).

The moment of truth. Dead on.

Once square is confirmed, locate the other end of the wall out from the reference (exterior wall). Wall baseline measurements in place with nails for holding the chalk line. Marks are also made at the other end of the wall (not shown here).

(C) Snap baselines for the sole plate.

Wall baselines snapped.

(D) Mark the openings and intersecting walls. I needed to mark the entrance to the bathroom and the two intersecting walls that defined the toilet area. I ended up changing where the toilet walls were located to match where the drain was, and also decided to change the door swing to make it more ergonomic. Once you lay things out in full scale, you will find you will need to adjust. The plans are never (exactly) right!

The red marks indicate changing the location of the partition walls to match where the rough plumbing for the toilet came in.

I decided to change the door swing to better accommodate ergonomics for entry and exit from the bathroom.

Step Two: Make a kit. Once the lines for the sole plates are marked out with the door openings and intersecting walls, it’s time to start marking out lumber and cutting. The key to framing any wall is to carefully mark out where all of the studs/jacks/cripples will be on the sole plate, and then transfer those marks directly to the top plate. This ensures that the ends of each stud/jack/cripple will be vertically aligned, making the wall relatively easy to square up and put in place.

(A) Cut the plates to size.

16′ lumber ready for marking. I will only use two pieces for the wall plates (sole and top) and the third will be a header for the false ceiling inside the wall.

Measuring out the length of the sole plate.

I put the measurement on the lumber so I won’t forget!

(B) Transfer the marks from the floor layout to the sole plate.

Sole plate on baselines, ready for marking.

Marking where the header of the toilet enclosure wall will go. The marks are transferred directly from the layout on the floor.

(C) Transfer the marks to the top plate.

Sole plate and top plate clamped up for marking. You want to mark both at the same time for accuracy and efficiency.

Marking cripple studs on top plate. These will be transferred to the door header when framing up.

If you want a 16 oc spacing, you have to offset the first one from the end by 3/4″.

(D) Make a cut list. This is done by methodically going through each mark on your top and bottom plates and figuring out how many studs (vertical pieces of lumber) you need and of what kind. There are four kinds of studs: Common (or just “studs”), Cripple, Jack, and King. Common studs are what you’ll have the most of. They are the height of the finished wall MINUS the thickness of the sole and top plates. For an interior wall with just one of each, that’s wall height -3″. With a double top plate, it’s wall height – 4-1/2″. In my case, the wall was going to meet the undersides of the trusses, which were angled to form the cathedral ceiling. So I had to use a plumb bob to find where the inside edge of the wall would touch the truss and measure from there.

Plumb bob lining up the edge of the wall to the truss. It’s actually pointing to the wrong line in this picture, (the correct line is the one on the lower right) but you get the idea.

Marking the bottom of the truss.

Mark on bottom of truss directly above the inner edge of the wall (i.e., the face of the wall towards the bathroom). Finish nail is in place to snap a chalk line.

Chalk line snapped on bottom of trusses to align the wall when it’s raised.

Back to the types of studs. Cripple studs are short studs that connect the tops/bottoms of wall openings to the sole or top plates. So, you’ll have a few of these wherever you have a door or window. In this case, I had a door and needed to place cripple studs between the door header and the top plate. Jack and King studs are what form the sides of the wall openings (windows/doors). The jack stud provides vertical support for the header while the king stud sits right next to the jack stud and provides stability to the header. The king stud is the same length as the other “common” studs but has a different name due to its function and location within the framing.

Door framing showing relationships between framing members. The cripple studs go above the header (where the hammer is). Note that the bottom of the door has the sole plate going right across. This will remain until after the wall is lifted and secured in place to make the wall assembly stiffer and easier to lift. It’s a simple matter to cut this out with a handsaw after the wall is up.

Once all of the various studs have been counted (and double counted), I put them into a table called a “cut list” to make sure that I didn’t leave anything out and that I had all of my measurements correct. I also put in the materials for the headers and the 4×4 header supports for the two smaller walls for the toilet area. Take some time to double check your work here because if you make a mistake and cut all your studs 4″ too short, you’ll have a lot of extra firewood and an unexpected trip to Home Depot.

Cut list. Makes it easy to get an assembly line going and helps keep track of where all of your parts are.

Cutting station. I couldn’t get my fancy (and too heavy) miter saw stand up here, so I improvised. Worked great!

All studs, cripples, jack studs, plates and headers stacked and ready to roll!

Step Three: Assemble the kit. This should be the easy part, right? Just separate your top and bottom plates, scatter your studs and arrange your headers and start banging away!

Kit components aligned on the floor, ready for assembly.

Well, not so fast. There are a few subtleties that bear mention when putting this thing together. First and foremost, you need to plan for a logical assembly sequence so that you avoid having to nail components awkwardly, or worse, have to disassemble a part because you couldn’t get to it. For this wall, I made several sub-assemblies so that I could accurately nail them together without interference from adjoining components. These sub-assemblies included the header, jack and king studs for the door, and header supports for the two walls separating the toilet area.

King and jack studs for door are pre-assembled. It’s a lot easier to face nail these two together when sitting flat then it is to try to bang it together when on its side and you have a floor and other studs to deal with.

Door framing subassembly with header, king, and jack studs. Also a partial assembly for the toilet wall header support (the one with the 4×4). I only nailed one king stud so that I could easily slide the header onto the support once the wall was up. I would then be able to nail the second king stud in place on the other side. This is a good example of thinking several steps ahead to avoid unpleasant problems in the future.

A good place to start is at one of the corners. I started with the sole plate.

Sole plate complete.

The other issue that you have to deal with are imperfections, both with your materials for the wall and the surrounding structures where the wall will go. Wood is rarely perfect. Some lumber can be badly warped. In some cases, you can take the worst pieces and use those for cutoffs, like cripple studs, where the warp won’t matter as much. Also, you can use warped lumber for the inner studs, where it doesn’t matter very much. Save your straightest pieces for the ends and the door framing, where that alignment matters most. You can also use leverage and beaters (sledgehammers) to “persuade” recalcitrant pieces of lumber into place.

Because of variations in the height of the floor (long story) I needed to put shims underneath some of the studs so they would be aligned with the plates.

Using a “cheater bar” to untwist lumber for nailing. I attached a 2×4 to the inside of the stud and then pulled like hell while I nailed the end to the top plate. I then removed the cheater bar.

Securing the top plate.

Wall complete and ready to raise!

Step 4: Raise the wall. Now it was finally time to raise the wall. Because it was inside the structure, I couldn’t use the wall jacks that I used for the exterior walls because the lumber used for the jacks would not fit under the ceiling. So I had to do this the “old fashioned” way with some helpers. The interior wall framing is lighter because it has no sheathing, and is also “flexible” meaning that I did not bother to perfectly square it up before I raised it. This is because it was going to fit between the floor below, lower truss chords above, and abut against an adjacent wall. So long as I had marks on the floor for the sole plate and marks on the truss chords for the top plate, and these two were plumb to each other, I could be reasonably certain that the wall would be plumb and in alignment with the rest of the framing.

Wall raised and in place.

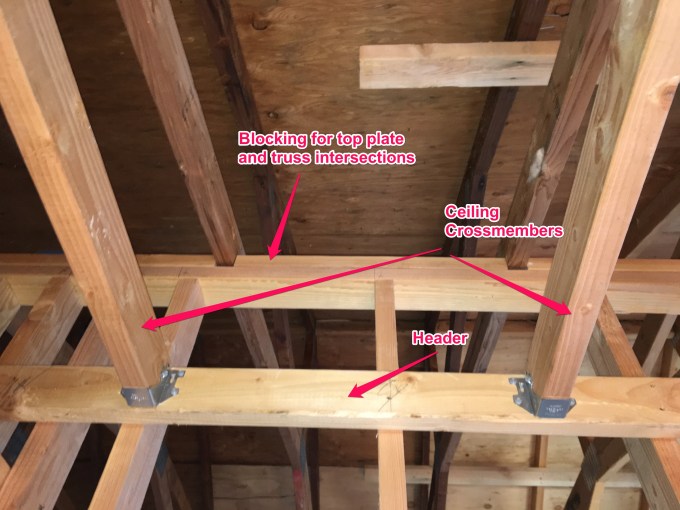

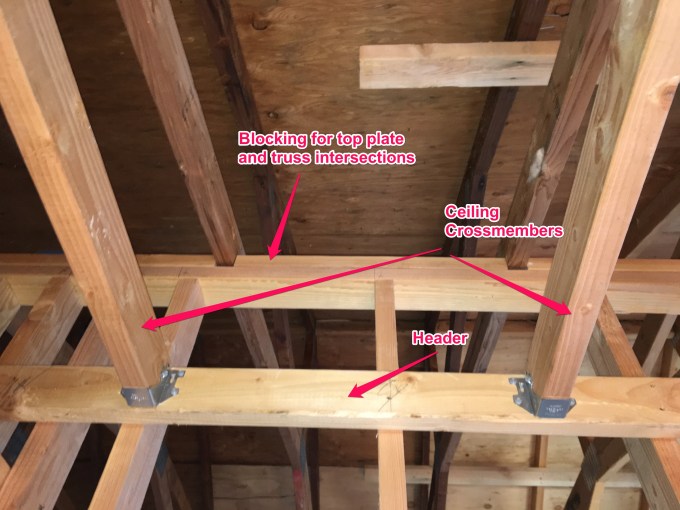

Because the main wall intersected the slope of the cathedral ceiling, I had to make a few accommodations. Specifically I had to install blocking on the top plate between the trusses to lock in the top of the wall. See the following picture of the false ceiling.

Step 5: Finish the interior details: Lastly, I had to construct a false ceiling on the other side of the wall and add a couple of partitions. Since I wanted the toilet to be separate and isolated when necessary, I had to put in walls that accommodated pocket doors. Pocket doors require an entirely different framing system. There are many types of systems that use basic materials to do the framing, but from a DIY standpoint, I found it more expedient to just buy a kit. The instructions were pretty straightforward, and as long as you’re accurate with the measurements, it’s largely foolproof.

False ceiling assembly detail showing the header and the false ceiling cross members.

Hangers for pocket doors installed. The headers for the doors will rest on these and when the door kits are installed, these will form the walls for the toilet area.

Pocket door headers installed.

Pocket Door Kit Instructions. This is the easiest solution.

Pocket door installed. I couldn’t find a picture of the framework (!)

The last thing I did was to cut out that piece of sole plate that was interfering with the door. If you recall, I constructed the wall with a continuous sole plate to help hold it together when the wall was raised. Now that the wall framework was finished, it was time to clean up that little detail.

Door opening with sole plate in place. I’m going to take care of that presently.

Sole plate is now cut for the door opening.

Now that the interior framing is in place, it’s time to proceed to the next step: rough plumbing, electrical, and data lines.